Quite a few companies that have pledged to achieve carbon neutrality have shifted from carbon offset scheme to reducing carbon footprint in supply chains, an approach that can prevent greenwash and increase brand credibility. Major brands such as Nestle, Gucci, and EasyJet have announced to decarbonize their supply chains. But what are the methods and challenges of supply chain decarbonization?

.jpg)

(Photo: Freepik)

Supply chain emissions account for as much as 80% of global corporate emissions, including the procurement and transportation of raw materials from suppliers, which is much higher than the emissions generated by the company's operations. Therefore, brand owners need to engage their suppliers to decarbonize their supply chains.

Apple, for example, has achieved carbon neutrality[1] for their own operations since 2020 by purchasing 100% renewable electricity and carbon offsets. However, more than 90% of their emissions come from the supply chain, prompting them to establish a series of supplier cooperation mechanisms to ensure net-zero emissions by 2030. Apple is not an exception. Industries that produce consumer goods tend to have a higher proportion of emissions coming from their supply chains. Therefore, how to work with suppliers to reduce carbon emissions will be a major challenge for businesses in the next five to ten years.

Supply chain influence shall not be underestimated

Figure 1 below illustrates the distribution of emission sources in various industries. Industries like cement and steel primarily emit from the manufacturing process, which is why Scope 1 emissions account for over 60% and 70%. For these industries, carbon reduction in the supply chain is relatively less urgent, with the primary focus being on reducing emissions and utilizing renewable energy (due to the higher electricity consumption in such sectors).

.png)

Figure 1. Emission sources of various industries[2]

You may wonder why the oil and gas, as well as metal mining industries, which are not consumer products, account for such a significant share of Scope 3 emissions. This is because large amounts of emissions are generated in the phases of "processing of sold products" and "use of sold products," both of which fall under Scope 3.

In industries such as food, information technology, healthcare, and financial services, the major emission sources often stem from "purchased products and services" and "investment." The former involves the purchase of raw materials, with common emissions reduction methods including substituting raw materials or using recycled materials. The latter involves adding other review criteria before investment, such as the financial industry's lending standards, which incorporate a company's sustainability performance, making it challenging to obtain financing for poor performers.

Three pathways to supply chain decarbonization

There are common collaborative carbon reduction methods, including establishing supplier scoring mechanisms, introducing management systems, and utilizing industrial cooperative development programs.

1. Supplier scoring mechanism (Supplier code of conduct)

Companies can categorize their suppliers into various tiers, establish emission standards for each tier (or each company), and evaluate the suppliers' annual ESG performance, with the results incorporated into annual procurement criteria and performance tracked continuously. This method is quite direct and effective in linking carbon reduction practices with procurement decisions and achieving a constraining effect, as long as the emission standards are properly established.

Additionally, downstream brand owners can play a more active role, providing education, funding, or technical advice to enable suppliers to quickly adapt. For example, HP has established a supplier scoring mechanism and regularly raises the standards for supplier environmental management[3]. In addition, they have found opportunities to reduce operating costs through this mechanism, such as switching from air freight to sea freight when transporting their Visual Collaboration Studio products, which saves USD 7,000 and 900 tonnes of CO2 emissions per shipment.

2. Digital management system

This method is particularly suitable for energy and carbon emission management. Traditional manual input can pose challenges for enterprises with multiple suppliers or operational sites. Additionally, the criteria and emission factors they follow in their calculations may vary significantly, leading to distorted data. Therefore, the introduction of digital management systems can improve both efficiency and information transparency, enabling enterprises to identify and address problems. For instance, an energy management system can promptly detect and address abnormal power consumption.

The number of companies adopting digital management systems is increasing, while systems are being upgraded. In the future, systems that include renewable energy certificate management and carbon asset management may be widely adopted. For example, Foxconn has implemented a supplier carbon management system, requiring suppliers to submit verified data on annual carbon emissions, carbon emissions per unit of output, and carbon reduction performance to conduct an energy saving and carbon reduction performance assessment. The results will serve as a basis for suppliers to increase or reduce orders and to optimize and eliminate their products.

3. Industrial cooperation development program

Launching initiatives within the same industry can not only facilitate effective supply chain management but also reduce reporting and data management efforts for companies with shared suppliers, as they only need to submit environmental data in a single format once. Unlike the management system mentioned above, which is often limited to companies and their own supply chains, a cooperative program covers a much wider scope that can lead to industry-wide carbon reduction.

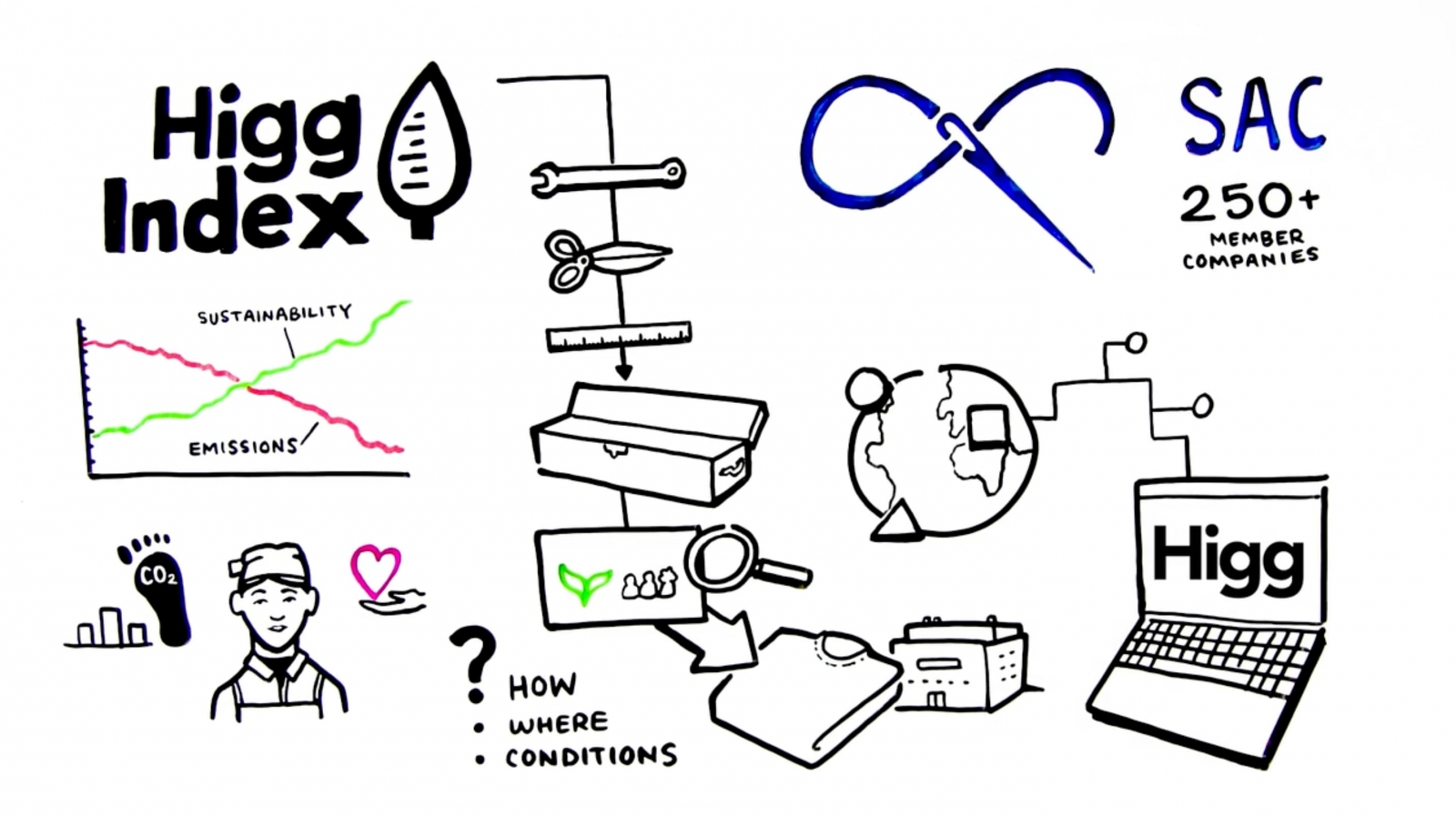

A well-known example is the Higg Index developed by the Sustainable Apparel Coalition. It helps footwear and textile industries of all sizes assess the environmental, social, and labor performance impacts of their products at each stage of the product lifecycle and identify opportunities for improvement. Participants can submit data, either calculated independently or provided directly, which will be verified by a third-party organization in partnership with the platform and made public for other members to compare and select.

The Higg Index is a suite of tools for the standardized measurement of value chain sustainability (Image: Sustainable Apparel Coalition)

Challenges facing carbon reduction in supply chain

Supply chain decarbonization is gradually becoming a trend; however, there are still some challenges to overcome in its development process. Firstly, there is the difficulty in reaching a consensus on carbon reduction with suppliers. A brand may have hundreds of suppliers, further divided into multiple tiers. Suppliers in the outer tiers may be smaller in scale and may consider abandoning orders due to the high effort and costs involved in carbon reduction. Therefore, the primary challenge lies in enhancing the willingness of suppliers while maintaining a cooperative relationship.

Secondly, data collection can be problematic. Since Scope 3 emissions can be divided into 15 categories, and each company has its own set of upstream and downstream suppliers. For companies with tens of thousands of products and high supplier turnover, collecting comprehensive data can be particularly difficult, highlighting the need of introducing a digital management system.

Although Scope 3 emissions contribute significantly to emissions in many industries, the underlying causes of these emissions may vary greatly, leading to different carbon reduction strategies. Therefore, companies need to consider industry characteristics when developing a cooperative program to ensure feasibility.

Related News Greenwash Green Power Carbon Offset

[1] Including the setting of emissions reduction targets, third-party verification of carbon emissions, etc.

[2] Data from CDP reports.

[3] Including the setting of emissions reduction targets, third-party verification of carbon emissions, etc.